STEP

Remember to bed the pads in, braking gently for the first 100 miles or so

This is the broken wire when it is off of the car

FRONT BRAKE PAD REPLACEMENT

(project by Mark Booth)

| OVERVIEW | TOOLS |

|

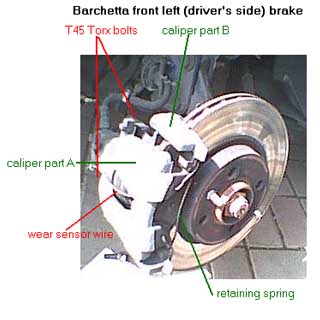

The front brakes are of the sliding caliper type, with a single piston. The left (driverıs side) brake is fitted with a wear sensor. To replace the pads, the piston-carrying part of the caliper (part A in diagram) is removed from part B, which is fixed to the hub. I understand there may be 2 types of brakes fitted; check you have the correct replacements before starting work. This car is a 1997 model with ABS and Bendix calipers.

|

2 large flat-bladed screwdrivers T45 Torx socket Brake cleaner Copperslip, or similar brake lubricant |

| WARNING | |

|

Bleeding the brakes on an ABS equipped car should not be attempted leave it to your dealer. However, there should be no need to do so for this job. |

|

| WHAT YOU HAVE TO DO | |

|

STEP |

ACTION

|

|

The

steps below use this diagram for visiual reference to parts

|

|

|

1

|

Undo the brake fluid reservoir cap. If your fluid level is at or near the maximum level, itıs likely fluid will be pushed out when the caliper pistons are pushed in place a cloth around it to catch any (it eats paint, remember). |

|

2

|

Apply handbrake, chock the rear wheels, and jack up the car. Remove front wheels. Start at the left (driverıs side) wheel this one has the brake wear-sensor. |

|

3

|

Clean the caliper with aerosol brake cleaner (put a cloth immediately underneath to avoid making a mess) avoid breathing any dust. It may not contain asbestos, but it still wonıt do you any good. |

|

4

|

Unplug the wear-sensor, and pull it backwards to slide if off itıs mounting. |

|

5

|

Prise off the retaining spring beware, it might fly off! |

|

6

|

Use 2 flat screwdrivers between the disk and the edges of the inner brake pad to slowly push back the piston be careful not to damage the dust cover. |

|

7

|

Prise off the 2 plastic caps, and undo the bolts that secure the caliper halves together youıll need a T45 Torx socket. |

|

8

|

Wriggle off the caliper. This is a bit tricky as the inner brake pad has a 3 pronged clip that fits inside the piston. Once removed, do NOT allow the caliper to hang from the brake pipe either hang it up using a piece of wire, or put it on top of the disk. Remove the outer pad. |

|

9

|

Scrape off all the caked-on dirt, and lubricate the edges of the pads where they contact the caliper. Also lubricate the prongs of the inner pad, and the rear of the outer pad (this should prevent any squealing). |

|

10

|

Fit the new inner pad into the piston - avoid contaminating the pad surface. Thread the wear sensor wire through the caliper. |

|

11

|

Fit the outer pad into part B of the caliper. |

|

12

|

Refit part A of the caliper, and tighten the bolts. Refit the retaining spring |

|

13

|

Slide on the new wear sensor, and reconnect the plug. |

|

14

|

Gently depress the brake pedal a few times, then check the tightness of the caliper bolts and security of the retaining spring. |

|

16

|

Refit the wheel. I like to check roadwheel bolts with a torque wrench 100NM is the usual for a steel wheel, less for an alloy. |

|

17

|

Remember to bed the pads in, braking gently for the first 100 miles or so |

|

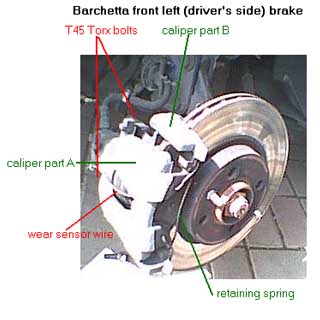

It

is also usual for the brake wear sensor wire to cut all the way through

(check your's every time you get under the car, it's on the drivers side)

|

And hereıs why my wear sensor didnıt work only 1 strand is holding the wire on! Because of the way the wire had been routed, the disk wore through it before the sensor contact was exposed. |

|

|

|

This is the broken wire when it is off of the car

|

|