| WHAT

YOU HAVE TO DO |

|

STEP

|

ACTION

|

|

1

|

Undo

the nuts holding the windscreen wipers and remove both wiper arms.

|

|

2

|

Undo the

large 22mm nuts holding the drive spindles for the wipers through the

body. [These may well need freeing up with WD40 if the water has caused corrosion in this area]. It is easy for the spanner to

slip and scratch the paint here so take care.

|

|

3

|

Undo the

6 "star drive" bolts that hold the front valance in place (4 in the front,

1 either side of door-shuts) and remove the front valance. (You have the choice of either leaving the valance upside down on the suitably protected bonnet or disconnecting the water-washer hose (probably need a heat-source to soften it up) and removing and storing the valance somewhere safe)

|

|

|

|

4

|

Once

the valance is removed, the whole wiper mechanism is exposed. Liberal amounts

of grease on all connections may solve your problem of "juddering" or slow

wiping. (I use spray Commer grease to get into all the joints). If that

is the case, you will soon find out by turning on the ignition and operating

the wipers. If the motor turns smoothly and the mechanism is good at all

speeds, then simply refit the valance and thank your lucky stars! If grease

does not solve your problems, then proceed to taking out the motor as below.

|

| |

|

|

5

|

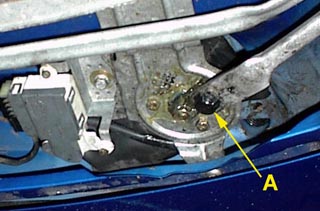

Start by

undoing the 13mm nut ³A² that secures the wiper mechanism to the centre

of the motor and freeing up the wiper mechanism. If you then undo the

four 10mm nuts ³B² that hold the wiper mechanism to the car body at the

bottom of the windscreen, the whole mechanism can be lifted out in one

piece.

CAUTION.

You have now upset the position of the, park (initial wiper position),

mechanism. Take special care when re-installing as per 8 below

|

|

|

|

6

|

Next

undo the devices that hold the motor in place. One is a 10mm nut located

on the motor body ³C²; the other is a star-drive bolt located on the front

car body (need the bonnet open to reach it). You will also have to disconnect

one electrical connector and then lift out the whole of the motor. (Use this opportunity to ensure the drain-hole in the body under the motor is clear and no rust has started there) |

|

7

|

Hold

the motor in a vice or similar, carefully strip off the rubber glove and

inspect motor body. If the motor body is badly rusted as mine was, wire-brush

and paint with Finnigans Hammerite or similar. [I used black waxoil on top of the paint in an effort to stop further rusting.] Then undo the 2 alan screw bolts on the top of the motor case

and withdraw top part of motor carefully. Check the roller bearing is well

greased and turning feely. Grease if necessary. (I then sprayed some WD40 inside the motor to keep all intact.) Photo opposite shows motor painted,

ready to re-install the rubber ³glove² around it. |

| |

|

|

8

|

When

reinstating in the car, fit the motor first and then the wiper linkage to

the motor. Do not fit the valance yet. Fitting is the reverse of dismantling

EXCEPT as mentioned in Step 5, you have upset the ³parking position² for

the wipers. |

|

9

|

To

overcome this problem do not refit the arm with nut ³A² shown on Step 6.

Instead, once the motor and all linkage mechanism are re-fitted, turn the

wipers on and off to make sure the motor is in ³parked² position. Then,

using sticky tape on the ends of the drive shafts in lieu of re-fitting

the wiper blades, offer the linkage up to the motor drive and trial-fit

with nut ³A². Then try the wipers again, watching the sticky tape to ensure

the wipers donıt ³kick down² before starting the upward sweep. Re-adjust

linkage as necessary until you are sure the wipers just move upwards. The

object of this exercise is ensure that the linkage is aligned to the motor

in such a way that the wiper blades wonıt ³kick down² when you first switch

them on (and scratch the valance when they do) |

|

|

|

|

10

|

Once

you are satisfied you have it right, remove sticky tape, make sure all is

tight and then refit valance (donıt forget washer hose if you removed it)

and wiper blades. When re-fitting the valance, it is worth putting liberal

amounts of grease between the drive spindles and the valance in an effort

to slow water ingress to this area. |

|

11

|

Test

and go and have a beer or six on the money you just saved. (A new motor is about £180 plus fitting costs!) |